District heating (term)

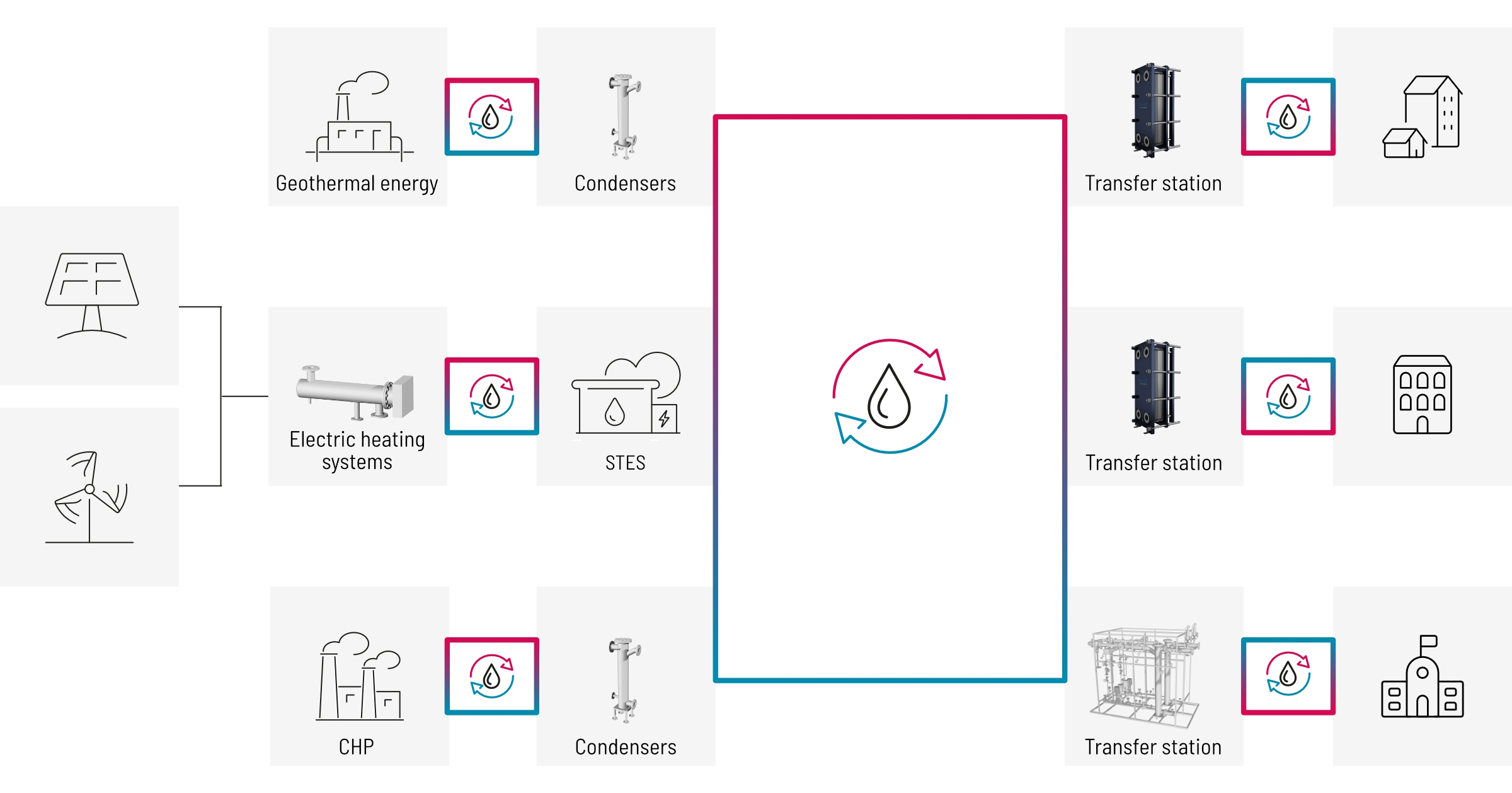

District heating is a surplus of heat generated in various different industries, e.g. in power generation via cogeneration in combined heat and power plants or in steel production or processing, that is subsequently used in building services to supply heating and hot water. However, a variety of suppliers could be considered a „source“ of waste heat, such as geothermal power plants, seasonal large-scale heat storage, and the like.

Examples of suppliers of district heating networks:

- Combined heat and power (CHP) plants

- Biomass power plants

- Geothermal power plants

- Solar thermal power plants

- Large-scale seasonal thermal energy storage (STES) (Wind/solar power)

- Industrial enterprises (steel production and processing,…)

Due to the energy losses occurring when transporting heat via an isolated pipeline system with hot water, the efficiency of the respective district heating network decreases the bigger the radius of residing recipients. For this reason, the consumers of a district heating network are usually located within a radius of less than 20 kilometers from the supplier.